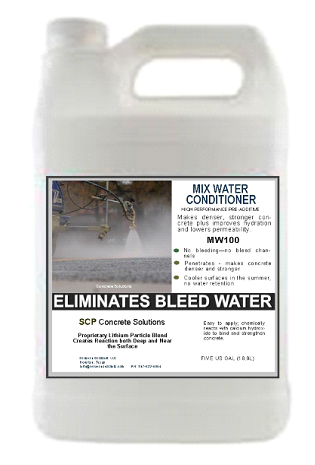

MW100 is a high-performance pre-additive that is added to the water at the batch plant before the cement, aggregate and admixtures; it controls segregation and stratification of aggregate and virtually eliminates all bleed water, in addition it hydrates the lime much more completely providing a more impermeable and high-performance concrete.

MW100 is a complex catalyzed silicate that initially forms an integral colloidal gel membrane prior to initial set. This restricts the rapid evaporation of surface water even in gusty wind conditions, which prevents shrinkage and provides an integral curing compound. Additionally, the colloidal gel mass serves as a thermal barrier that conserves heat generated by hydration during colder conditions and reduces heat absorption in hot weather. Through the additional initial mixing time, these Gel masses surrounding cement particles, or ‘hydration envelopes’, peel off of the cement particles, allowing additional gel formation, these peel off, and the process continues, resulting in approximately 20% more Portland cement hydration than control concrete. From 28 days to completion of hydration, the final chemical phase completes the last of the chemical process converting and reducing the remaining capillary voids present after hydration to near-zero.

To receive a Material Safety Data Sheet on any of our products please click here to send a request.